Enoline Solutions has more than 30 years of combined experience in the development and development of secondary and third party packaging equipment. We have assisted more than 50 happy beverage entrepreneurs. It doesn't matter if your beverage is packaged in a glass bottle, can, or keg, our team is able to create a custom solution that meets your production, space, and budgetary requirements.

The Various Containers For Beverages

Your wine, cider mead, or other beverages. are stored in different containers. There are a variety of options. In the three areas, companies often struggle to make the right choice. Our role is to help you in making your decision by suggesting the most suitable solutions. Beers and drinks particularly, are transported in containers called kegs. They offer the advantage of having more liquid per liter, and permit greater storage and transport. When it is time to create the final product, 2 containers are widely used in the market: the bottle or the can. Check out the top

fusibles emballeuse for website info including refroidissement automatique rapide montréal, beer variety packs, reduce packaging costs, endloaders case packing, pack variété canspiracy sur le thème tiki, solutions d'emballage durable, future packaging trends, food and beverage industry, avantages d'un processus d'automatisation de l'emballage pour votre entreprise, machines emballeuses, and more.

Glass Bottle Glass Bottle. Can

Beverages can be packaged in glass or PET bottles. Glass will look more expensive. In addition, glass is hygienic as well as pleasing to the eye and natural. Glass bottles are much more enjoyable than drinking from the can. It is advisable to pour your drink into a glass prior to you taste it. Today's beverage manufacturers are increasingly using cans for packaging due to a variety of reasons. One reason is that they are more efficient in conserving. Because the container is hermetic as well as transparent unlike transparent bottles, it blocks light and prevents air from getting inside. Also, it comes with an easier closing mechanism than a simple screwed lid. If you are in need of glass bottles, they can be used for the cooling or maturing of your beverages. Cans help you keep fresh hops. They are also durable vertically, so they can be stacked to help you save storage space in your warehouse. Cans offer unlimited design options and marketing opportunities. Steel and aluminum cans from Ecology are 100% recyclable. They require less energy than glass bottles, which must be washed over 30 times before they are recycled. But, a is recyclable and reused quickly for the same price in only 60 days. The average time for a can is of 280 days to be refreshed from a glass bottle. If ecology is your motivation, please don't ruin the environment by affixing plastic caps to your cans. This is an ecological catastrophe that is non-recyclable, which will cause oceans to be unsustainable. Use recycled cardboard packaging that is 100% recyclable. The SL-20 machine is able to make any kind of packaging, even those which are popular among consumers. Have you picked the right container? It is now time to finish the filling, packing, and palletization process prior to distribution. If you're dealing with large volumes, you need to figure out ways to automate these processes. And this is a good thing for you! Read the top canada complete production line for blog info including palettiseur automatique ontario, emballages en papier recyclable, emballeuse bière, automated machines, réduire les coûts d'emballage, équipement d’encaissage brasserie, tendances futures en matière d'emballage, ligne d'emballage, toploaders case packing, emballeuse brasserie, and more.

Why Not Automate Your Beverage Packaging

Hygiene

The primary reason for choosing an automated packaging system is hygiene. the use of unprofessional tools could result in contamination. It's not just an issue for health reasons and external ingredients in the beer, for example could significantly affect the flavor and authenticity of the product that could significantly lower the quality of your beverage. Safety is the main concern. In-house packaging systems could contain harmful agents, just like any other beer equipment.

Convenience

It is essential to be able to rely on an outside beer packaging company to package your beer into bottles or cans. You should also consider the cost of transporting the beer from your brewery and to the supplier. Even if the equipment for beer you own isn't the most advanced it could be heavy. It is recommended to invest in automated personal beer packaging equipment when your production reaches the limit of selling the beer outside of your brewery.

Control

Any beer equipment needs to be managed. Packaging machines aren't any exception: having a professional equipment allows you to manage every stage of the process of packaging, from cleaning to filling with caps for bottles or cans. It is important to monitor the process to avoid wasted alcohol, contamination or any other issues that could have a devastating effect on the months of work. Also, you are guaranteed the same product quality that manual work provides. This is very important for the consumer's point of view. View the most popular

good quality packaging machinery for more examples including best packing machines manufacturer canada, ontario packaging machine, fusibles emballeuse, machine emballage promotionnel québec, how to wrap a tray, machine d'emballage flexible, refroidissement automatique rapide québec, craft breweries, emballage réutilisable, preserve the quality of craft beer, and more.

Brand

The ability to have your own automated packaging system gives you a wide range of customization options. With it, you are able to design the packaging of your favorite beverage and start selling bottles or cans with your company's name. Marketing is all about branding. It can make your brand known and well-known. Stand out from your competitors! Change the format and the types of packs effortlessly.

Production speed

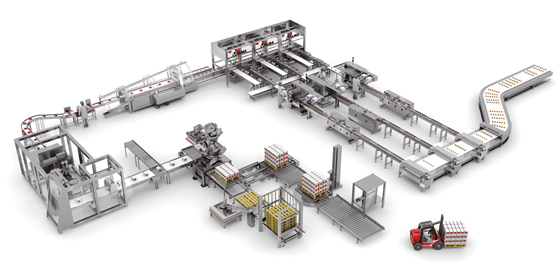

The professional automated packaging system's most valuable asset is its speed. It is able to be integrated in your beer equipment to greatly increase your production. You will be able to make bottles, cans and various other containers in a very quick period of time. You can take it to the next level. Our main solutions for beverage packaging. We offer a range of solutions from automatic filling machine to final packaging on pallets. This includes wrap around or side loading packaging machines. It is reliable, efficient as well as quick, flexible and reasonably priced. Read more- Best Advice For Picking Automated Packaging Machines bb17588 , Great Facts For Choosing Automated Packaging Machines and Best Advice For Picking Automated Packaging Machines.